PROCESS GAS AND COOLANT INDUSTRY

Customers benefit from the extensive know-how that CIME has gained from decades of experience in the chemical and petrochemical industry.

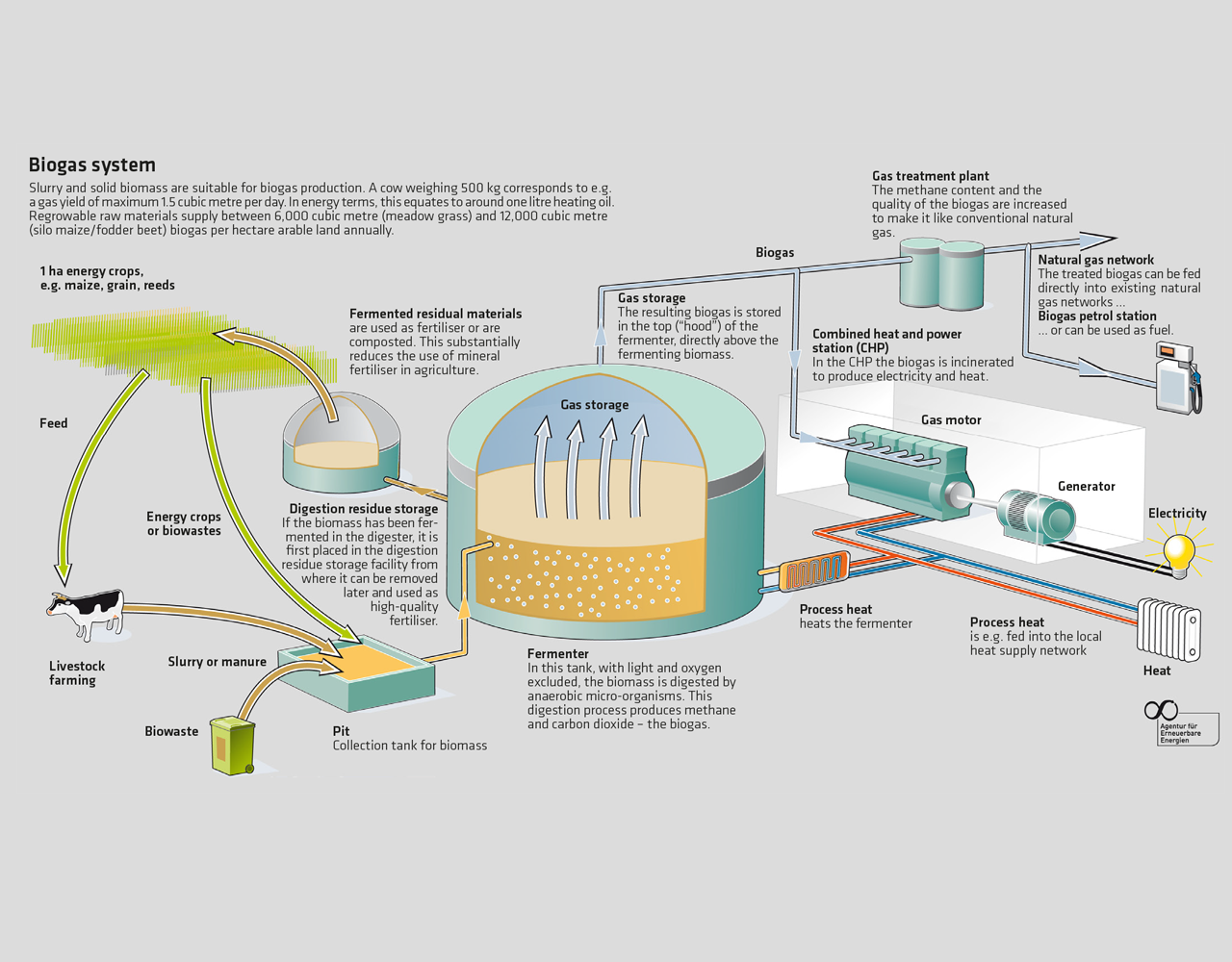

The use of biogas as an energy source will considerably help achieve the environmental objectives set nationally and internationally; be that reducing reliance on nuclear energy or the reduction of CO2 emissions.

WE AT CIME SUPPORT ALL THESE OBJECTIVES WITH OUR MORE THAN 43 AGENCIES WORLDWIDE.

For many years, Aerzen blowers and compressors have been conveying and compressing all types of gas and gas mixtures in plants of the chemical and petrochemical plants. Thereby, energy efficiency, plant safety and reliability are the decisive criteria. Based on this know-how and the experience gained, CIME offers products especially developed for the biogas market:

whether boosting the intake pressure of combined heat and power (CHP) engines and treatment plants for biogas (BGTP) or as an essential part of biogas injection plants (BGIP) for the compression of biomethane to inject into gas grids - CIME has the suitable blower or biogas compressor for each application. Customer-specific solutions can be offered from a wide array of machine sizes and design pressures.

All blowers and compressors can be used in hazardous areas Zone 1 and in Zone 2 as defined under ATEX Directive RL 2014/34/EU as well as the Machinery Directive, including the latest safety standard (EN 1012-3) and for Germany the DVGW* regulations.

*DVGW: German Technical and Scientific Association for Gas and Water

MOST EFFECTIVE BLOWER TECHNOLOGY FOR WASTEWATER

There are many options to apply methods to avoid damaging the environment. In the case of wastewater e.g. the ventilation of the sediment tank or the pressure ventilation of biological wastewater treatment systems. The oxygen introduction is important, for deep wastewater tanks, wastewater treatment systems with standard aeration tanks or natural clarification ponds alike.

There are many options to apply methods to avoid damaging the environment. In the case of wastewater e.g. the ventilation of the sediment tank or the pressure ventilation of biological wastewater treatment systems. The oxygen introduction is important, for deep wastewater tanks, wastewater treatment systems with standard aeration tanks or natural clarification ponds alike.

If the wastewater has already entered the natural cycle, ventilating lakes and rivers prevents additional contamination. When treating drinking water, rinsing the filters with compressed air ensures that perfect water is provided and natural water reserves are not used excessively.

Gas which occurs on landfill sites, digestion towers or gas which is produced when treating wastewater does not escape into the environment anymore or is not just burned. It is used sustainably to create energy to relieve the environment and remedy resource deficits. Due to the pressure increase of biogas blowers, the gas is transported to CHPs or generators where the converted energy can be used to heat buildings or greenhouses, for example. The produced gas is measured by CIME rotary piston gas meters.

During sludge drying processes, CIME positive displacement blowers can be used for the subsequent pneumatic transport of the dried sludge.

CIME products not only do their job in the examples given above. Just as there are many options to protect the environment, there are many areas of application for CIME positive displacement blowers, rotary lobe compressors and turbo blowers.