PROCESS GAS AND COOLANT INDUSTRY

The differences in compressor technologies can be found right where the demanding applications are. Where often highly critical processes gases and coolants are compressed. In the chemical, petrochemical, energy, food, or pharmaceutical industries. The demands on plant design, engineering, documentation and worldwide service in those industries are often just as high as the safety and environmental guidelines to be followed.

FROM APPLICATION TO HIGH-END SOLUTIONS

t is not the machine that determines the process – it is the process that determines the machine. This is our philosophy. Anyone as application-oriented as AERZEN invests heavily in groundwork. The kind that results in a solid understanding of the client’s business. The kind that forms the basis for the high-performance solutions that come from our design forge. State-of-the-art technologies for the most demanding process gas and coolant applications.

UNDERSTANDING THE PROCESS.

The philosophy and technical design underlying process gas and coolant facilities demand a high level of intelligence. After all, they are expected to work in the world’s most demanding industries. Often in highly critical applications. That is why CIME has gathered together its best minds in the Process Gas Division. A team of excellently trained specialists from construction, instrumentation, control, and project management. With international experience in all areas of process gas compression and transport. They operate in Germany, Hungary, and the USA. For markets and industries the world over.

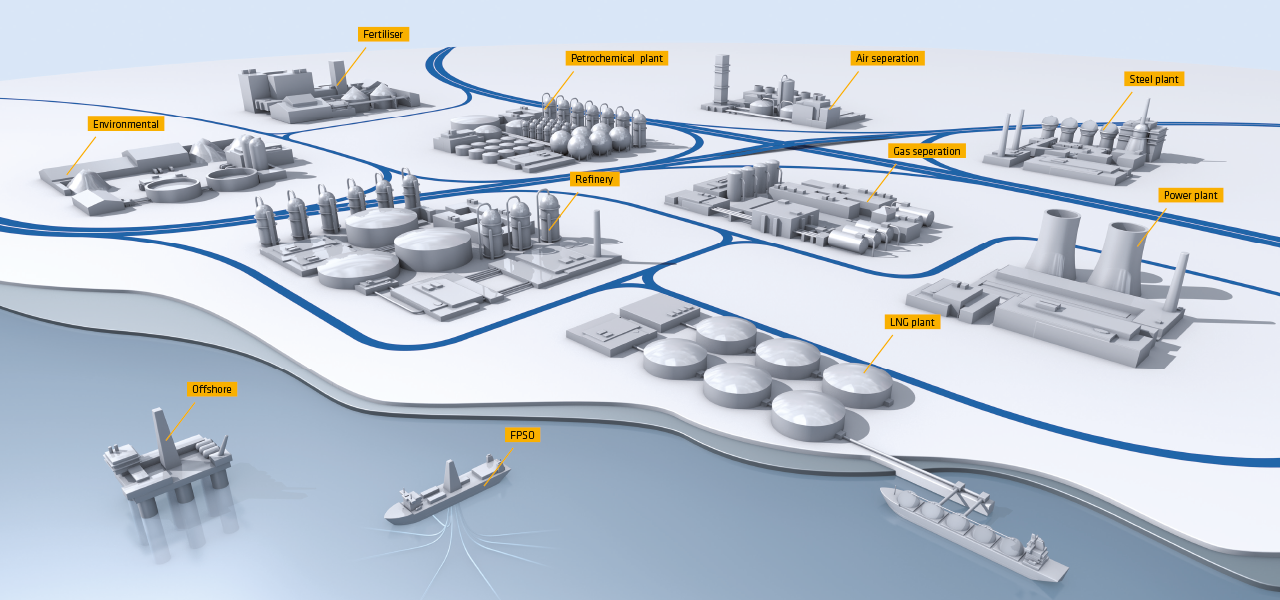

CIME range of applications in the process gas and cooling industry

Screw compressors and positive displacement blowers for applications in the process gas and cooling industry

MOST EFFECTIVE BLOWER TECHNOLOGY FOR WASTEWATER

There are many options to apply methods to avoid damaging the environment. In the case of wastewater e.g. the ventilation of the sediment tank or the pressure ventilation of biological wastewater treatment systems. The oxygen introduction is important, for deep wastewater tanks, wastewater treatment systems with standard aeration tanks or natural clarification ponds alike.

There are many options to apply methods to avoid damaging the environment. In the case of wastewater e.g. the ventilation of the sediment tank or the pressure ventilation of biological wastewater treatment systems. The oxygen introduction is important, for deep wastewater tanks, wastewater treatment systems with standard aeration tanks or natural clarification ponds alike.

If the wastewater has already entered the natural cycle, ventilating lakes and rivers prevents additional contamination. When treating drinking water, rinsing the filters with compressed air ensures that perfect water is provided and natural water reserves are not used excessively.

Gas which occurs on landfill sites, digestion towers or gas which is produced when treating wastewater does not escape into the environment anymore or is not just burned. It is used sustainably to create energy to relieve the environment and remedy resource deficits. Due to the pressure increase of biogas blowers, the gas is transported to CHPs or generators where the converted energy can be used to heat buildings or greenhouses, for example. The produced gas is measured by CIME rotary piston gas meters.

During sludge drying processes, CIME positive displacement blowers can be used for the subsequent pneumatic transport of the dried sludge.

CIME products not only do their job in the examples given above. Just as there are many options to protect the environment, there are many areas of application for CIME positive displacement blowers, rotary lobe compressors and turbo blowers.